1. What is a Powder Coating Oven and Spray Booth?

A powder coating oven and spray booth are essential for applying and curing powder coatings. The spray booth ensures even powder application, while the oven cures it into a durable finish. Together, they deliver high-quality, long-lasting coatings for metal, plastic, and composite materials.

2. Where are These Systems Used?

These systems are vital in automotive (car parts, wheels), aerospace (aircraft components), furniture (metal frames), and appliance manufacturing (panels, housings). They are also used in construction, electronics, and heavy machinery for corrosion-resistant and aesthetic finishes.

3. Cost of Powder Coating Oven and Spray Booth

Prices range from 10,000forbasicsetupstoover200,000 for advanced systems. Factors like size, heating technology (electric, gas), and features (e.g., infrared curing) impact costs. Custom designs may increase prices further.

4. How to Use Powder Coating Oven and Spray Booth

Pre-clean parts, adjust spray gun settings for even application, and maintain consistent oven temperatures (150–200°C). Regularly clean filters and inspect heating elements to ensure optimal performance.

5. How to Choose the Right System

Consider production volume, part size, and coating needs. High-output facilities need large, automated systems, while smaller shops may opt for compact models. Prioritize energy efficiency, maintenance ease, and vendor support.

6. Safety Tips for Powder Coating Systems

Ensure proper ventilation to avoid inhaling powder. Ground equipment to prevent electrostatic discharge. Operators must wear PPE: masks, gloves, and flame-resistant clothing. Regularly inspect electrical systems and oven components.

7. Why These Systems are Efficient

Modern designs focus on energy efficiency and reduced waste. Features like recirculating filters cut powder waste by 50%, while programmable controls enhance productivity and sustainability.

8. Q&A on powder coating oven and spray booth

Q: What industries use these systems most?

A: Automotive, aerospace, and furniture industries rely on them for durable finishes.

Q: Can they handle large parts?

A: Yes, custom systems can coat large components like car frames or machinery parts.

Q: Are these systems eco-friendly?

A: Yes, advanced filters recycle overspray, reducing waste and environmental impact.

Q: How do automated systems improve efficiency?

A: Automation ensures consistent airflow, powder recovery, and curing, reducing labor and material costs.

Q: What maintenance is required?

A: Clean filters weekly, inspect ventilation monthly, and replace worn parts as needed.

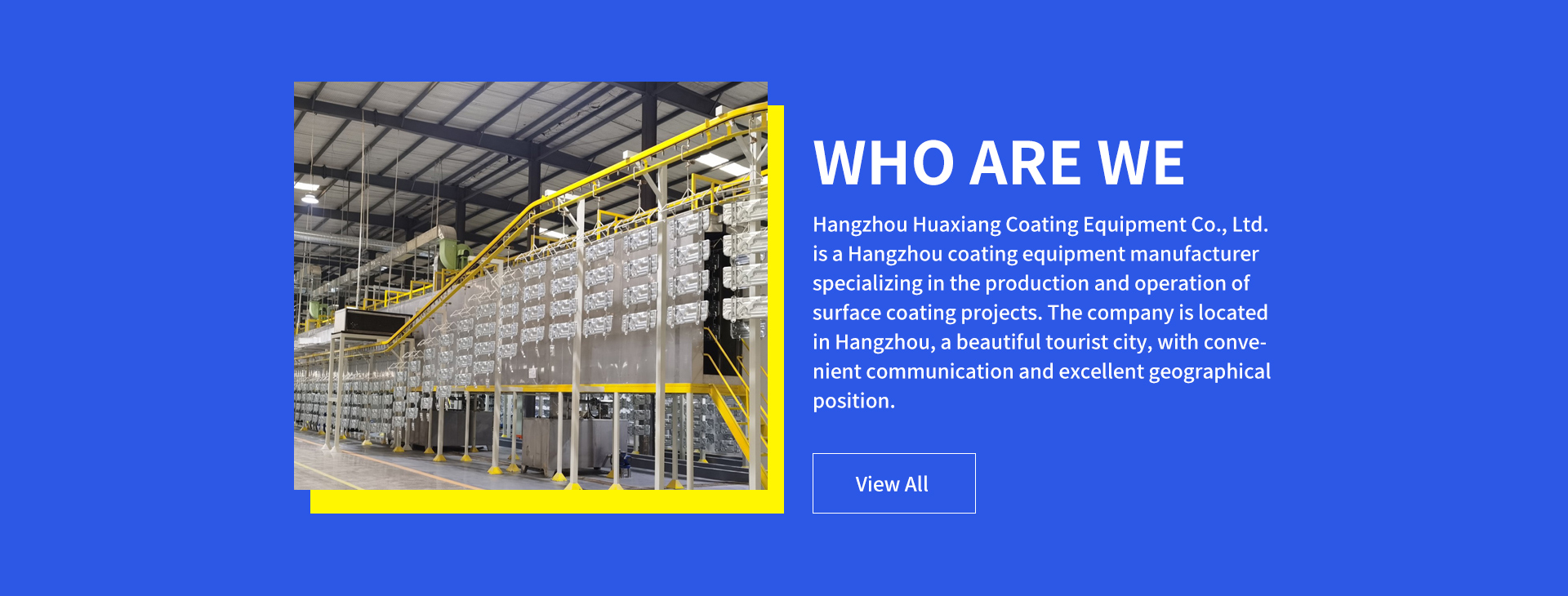

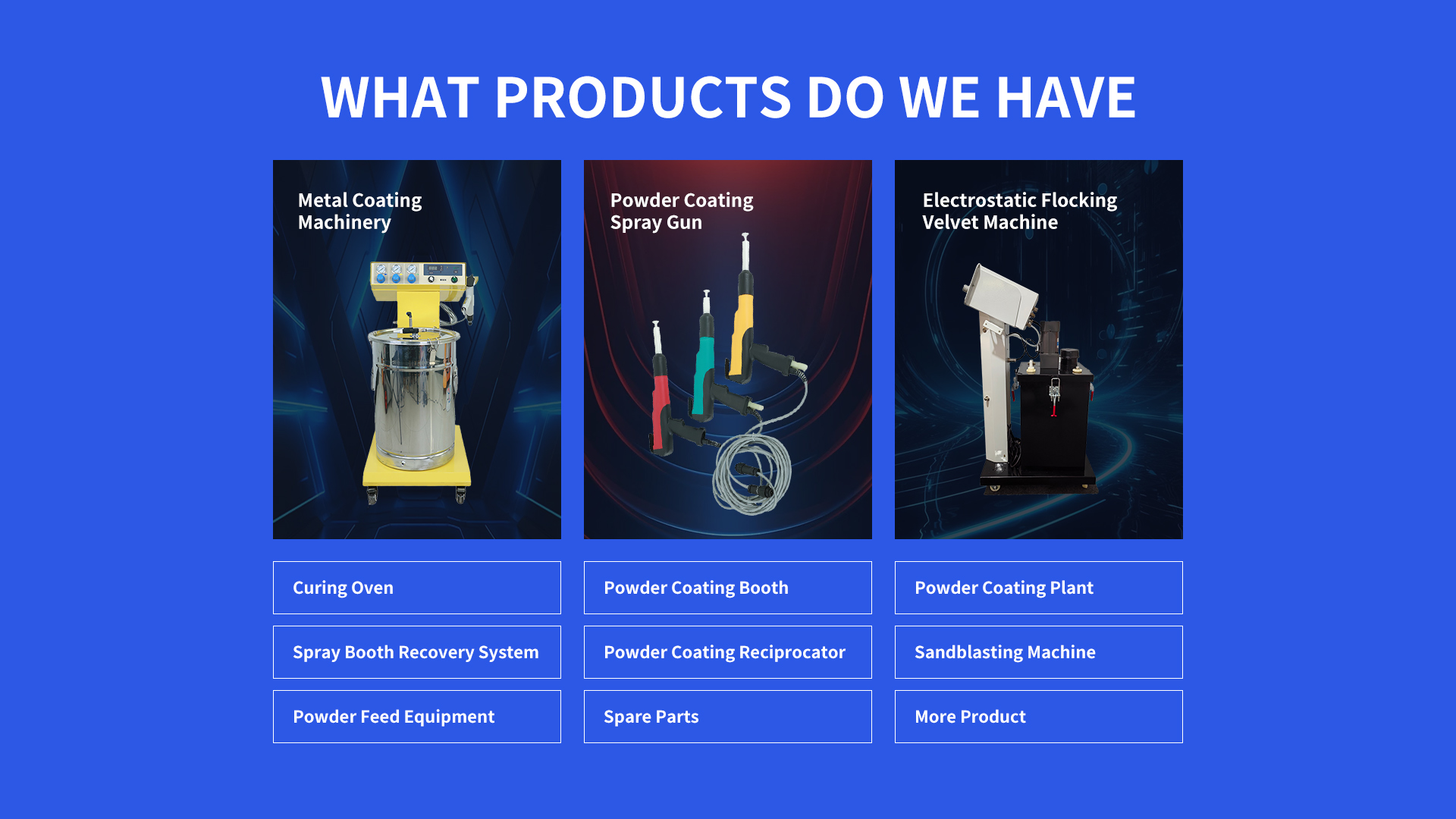

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com